"Digital Machine File" at TRUMPF for on-demand visualization of 150.000 machines

August 10th, 2022 Darmstadt, Germany

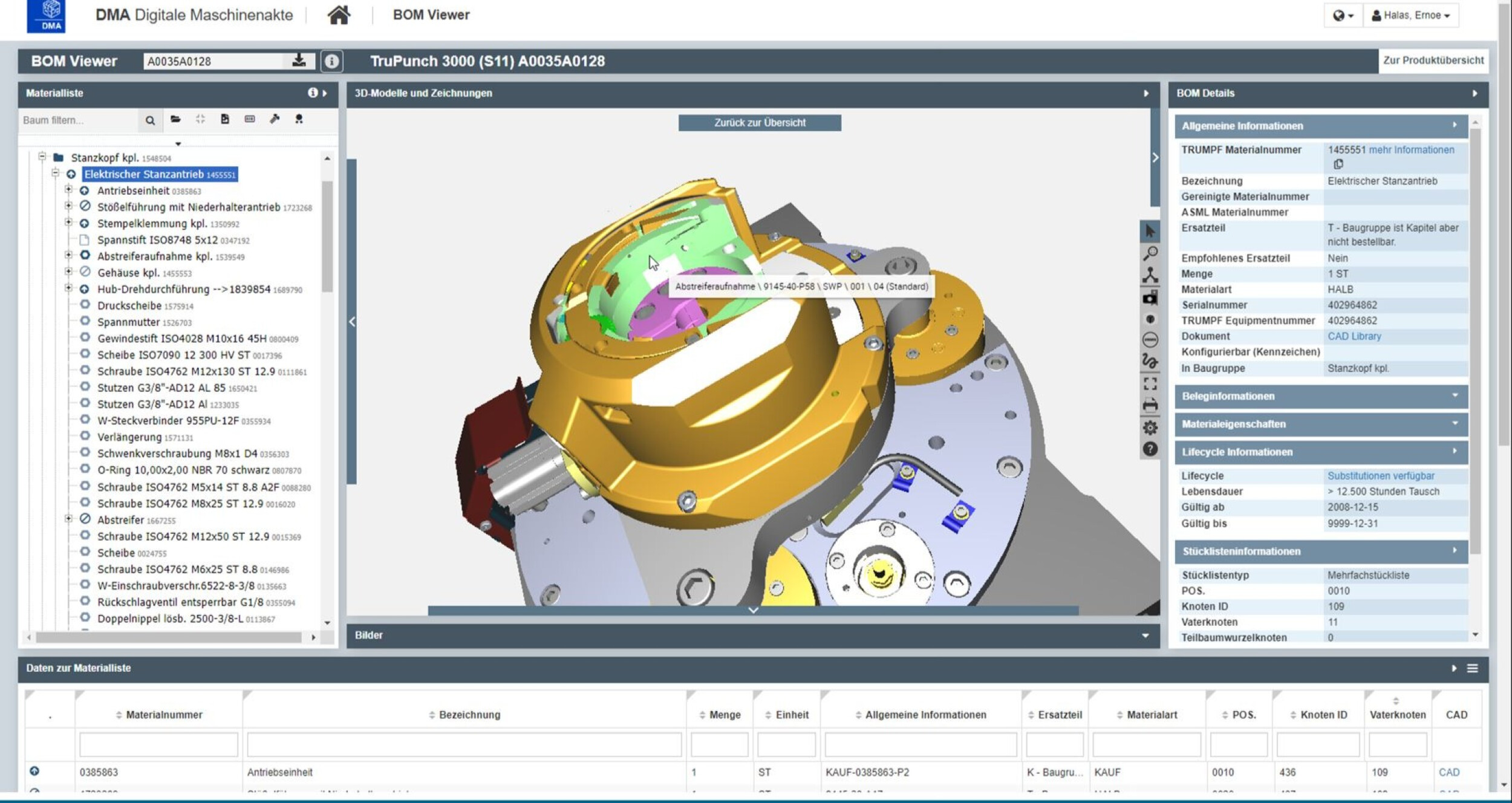

Digital twin as starting point for data-based services at TRUMPF: We are happy to support Trumpf on their digitalization journey by streaming 3D data to the "point of service" with instant3Dhub.

TRUMPF chooses Threedy

Trumpf's outstanding technology in the area of i.e. laser cutting and punching machines will be backed by instant3Dhub technology to stream 3D data to the "point of service" in future. Fully integrated into the existing tooling landscape YUNA by eoda, instant3Dhub enables the visualization of the Digital Twin for AfterSales & Service at Trumpf.

Challenges

Further developing and digitally networking of production technology, making it even more economical, precise and future-proof - that is TRUMPF. In doing so, the company wants to make manufacturing and its upstream and downstream processes more efficient. This also applies to internal processes. The digital twin promises great potential. As is often the case, the challenges lie within the data foundation and the target group-oriented visualization.

Goals

The first project phase in the creation of the digital Twin targeted goals such as:

Overarching content structure of the data integration platform

Interfaces to process leading core and non-core systems

Scalable interfaces to provide data to additional systems

Creation of logic within data structures

Visualization of one or multiple product instances

Embedding of existing multimedia content (3D, 2D, image, text)

Definitions of user groups with individual views

Context creation for a wide range of master and transaction data

The Solution

Our technology, instant3Dhub, have supported Trumpf to achieve its goals.

The first use case focused on in-house and field service, as the process optimization of spare parts research offered enormous potential.

During the life cycle of a product, its condition can change regularly or irregularly due to software updates, modifications, function enhancements and spare parts. For all these events, it is important to build a solid data basis and then define a suitable visualization structure, in order to implement the requirements as specifically as possible.

Today, the "Digital Machine File" visualizes more than 150,000 TRUMPF products and brings a wide variety of data objects from different systems into context at different time points, and visualizes the results in a user-friendly manner. The Digital Machine File connects all relevant data in a context-specific manner, thus enabling intuitive and efficient use of the information within the entire process chain.

Today, with more than 1,700 users worldwide, the "Digital Machine File" is a central component in the solution landscape throughout the TRUMPF Group. The "digital Machine File" serves as a single point of truth, and provides surrounding systems with individual product and status data.

In addition to service, this also benefits sales for example, which can use the information about the machines used and their expansions bundled in the digital machine file to make its processes more efficient, and its customer approach even more targeted.

Furthermore, the "Digital Machine File" is the optimal basis for the simulation of virtual production lines and further data analyses. For example for the creation of new digital services.

Terms