Getting Ready for Large-Scale Making

Ensuring that the transition from design and engineering to production is smooth, efficient, and cost-effective.

Production –

The Backbone of Product Development!

Collaboration

Early involvement allow production teams to provide input on design constraints, materials, and processes, reducing costs and optimizing output. Other feedback (e.g., defects or inefficiencies) helps Engineering and R&D refine future designs.

3D in Production

3D data ensures accurate production through digital twins and 3D measurement systems. These tools optimize workflows, detects defects early, reduce waste, and enable predictive maintenance for smoother operations.

Leveraging 3D Data for Smarter Production Workflows

Instant3Dhub introduces new ways of leveraging 3D data in production by fostering seamless collaboration across departments and suppliers by easily share and analyze 3D related data, reducing errors, and speedig up decision-making.

A 3D factory twin enhances operational efficiency without major IT overhauls by

Allowing real-time monitoring

Error predictions

Process optimization

Instant access to 3D visuals on the shopfloor ensures products match customer specifications, improves operational excellence and reduces rework by

Helping workers understand assembly requirements

Identifying defects quickly

Reducing scrap

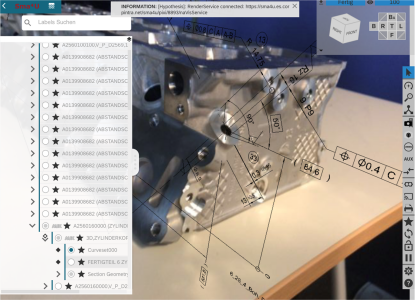

Last, but definitly not least, 3D measurement systems can

Improve part validation

Analyse root causes

Support ongoing inspections

Real Results from Leading Industry Players

See how our customers use instant3Dhub to solve complex 3D challenges, and get measurable results across teams.

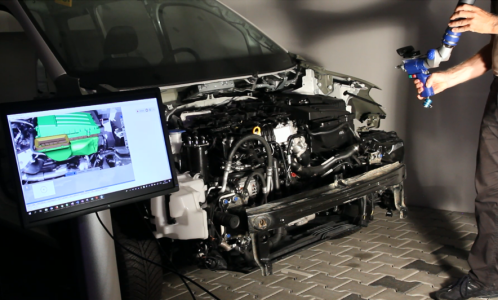

VW deploys AR solution for Geometric validation

November 16th, 2021 - Geometric validation of a vehicle design is a time consuming and costly process, since it involves constructing and inspecting Physical Mock-ups (PMU). Efficiency can be increased when this is done by assessing physical parts with virtual ones usi...

instant3Dhub for the industrial metaverse – Siemens LDA and 4Soft present their joint vision

July 17th, 2023 - Check out the joint partner presentation from Siemens LDA and 4Soft at prostep ivip Symposium 2023, Stuttgart: Instant 3D for the Industrial Metaverse - Collaboration across the Entire Product Lifecycle.

Joint Use Case and Roadmap Presentation with Mercedes-Benz AG

May 31st, 2021 - Watch our joint presentation with Mercedes-Benz AG at prostep ivip symposium 2021 - Industrial AR Clouds on Open Standards - and learn about our aligned roadmap.